OUR PROJECTS

Reverse engineering

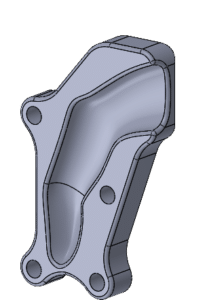

Car cooling liquid tank.

Initial problem

The scarcity of spare parts, whether they are original or alternative, in the local market, along with the limited durability of the few available, poses a critical challenge.

Solution

We carry out the 3D scanning and reverse engineering service of the original spare part. Through this process, our clients can design their own spare part, eliminating defects present in the original, such as sinks and weak areas, and making modifications to improve its shape and overall performance.

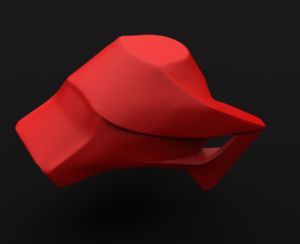

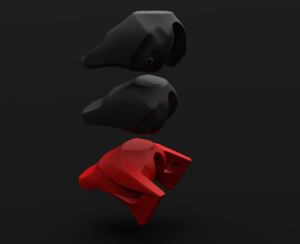

Excavator mechanical tooth coupling.

Initial problem

Lack of spare parts in the local market, both original and alternative, due to importation issues.

Solution

We provide 3D scanning and reverse engineering services for the spare part. Our client aims to produce alternative spare parts with modifications that suit their requirements. In this case, we have changed the manufacturing method from casting to machining to meet their specific needs.

Car bumper.

Initial problem

The shortage of spare parts, whether they are original or alternative, in the local market is critical for this product.

Solution

We provide the service of 3D scanning and reverse engineering of the same. The client wants to produce alternative spare parts.

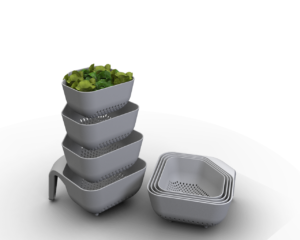

Strainer.

Initial problem

The company is looking to expand into a new market by producing a new product, but currently lacks the necessary blueprints or files and doesn’t want to spend resources on designing from scratch.

Solution

We provide 3D scanning services and reverse engineering services for physical products. Through digitalization, we enhance and modify the products, providing the company with high-quality products ready for production.

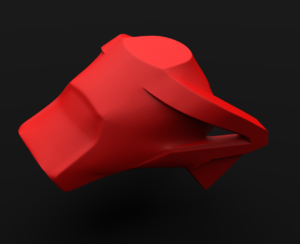

Milk jug.

Initial problem

The company is looking to expand into a new market by producing a new product, but currently lacks the necessary blueprints or files and doesn’t want to spend resources on designing from scratch.

Solution

We provide 3D scanning services and reverse engineering services for physical products. Through digitalization, we enhance and modify the products, providing the company with high-quality products ready for production.

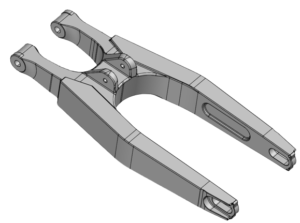

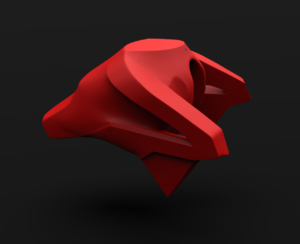

Motorcycle suspension.

Initial problem

The original model of this piece tends to break concurrently. This is a critical part of an off-road motorcycle, so its lifespan must be increased.

Solution

We conduct 3D scanning and reverse engineering of the same. During this process, we make essential modifications, changing the manufacturing method from welded sheet metal to machining, significantly increasing the part’s durability.

Metrology

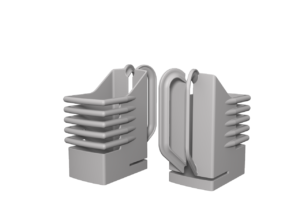

Generation of clamping devices.

Initial problem

Due to the complexity of the part, securely clamping it with a standard vise during the machining process poses a significant challenge, leading to substantial deviations.

Solution

The 3D scanning of the piece and the generation of jaws that replicate the volume. This allows for a larger contact area, ensuring that the part is held correctly and without deviations.

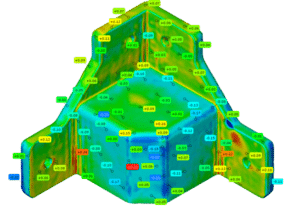

Quality control

Initial problem

Analysis of deviations in a 3D printer before starting large-scale production.

Solution

3D scanning of the piece and comparison with the CAD file. Obtaining deviation values in each axis, allowing for precise corrections to achieve a part with very tight tolerances.

3D Scanning

Dinosaur educational model

Initial problem

We aim to digitize the educational model to make it viewable on any device.

Solution

3D scanning of the piece, allowing the STL file generated by the 3D scan to be viewable from anywhere in the world.

Design

Are you interested in what we do?

We are a young company committed to providing precise results. Don’t hesitate to contact us, and we will develop a solution for your problem at no cost.